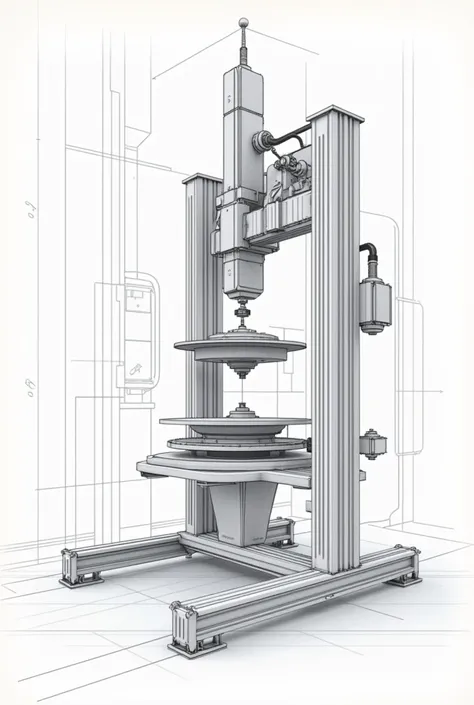

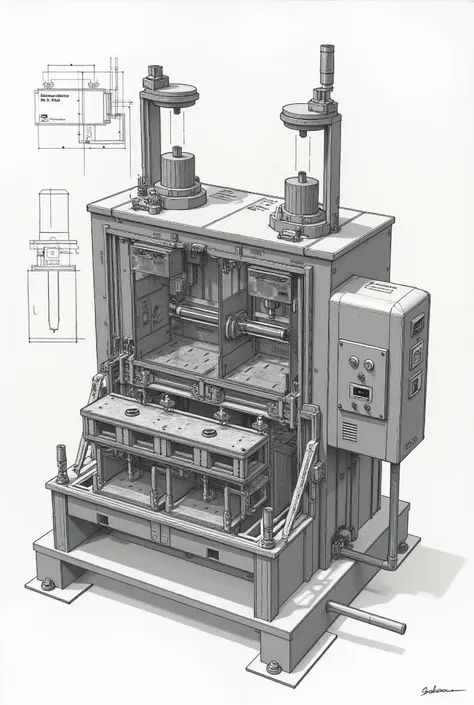

Make a simple sketch of the project without people in the less robust image

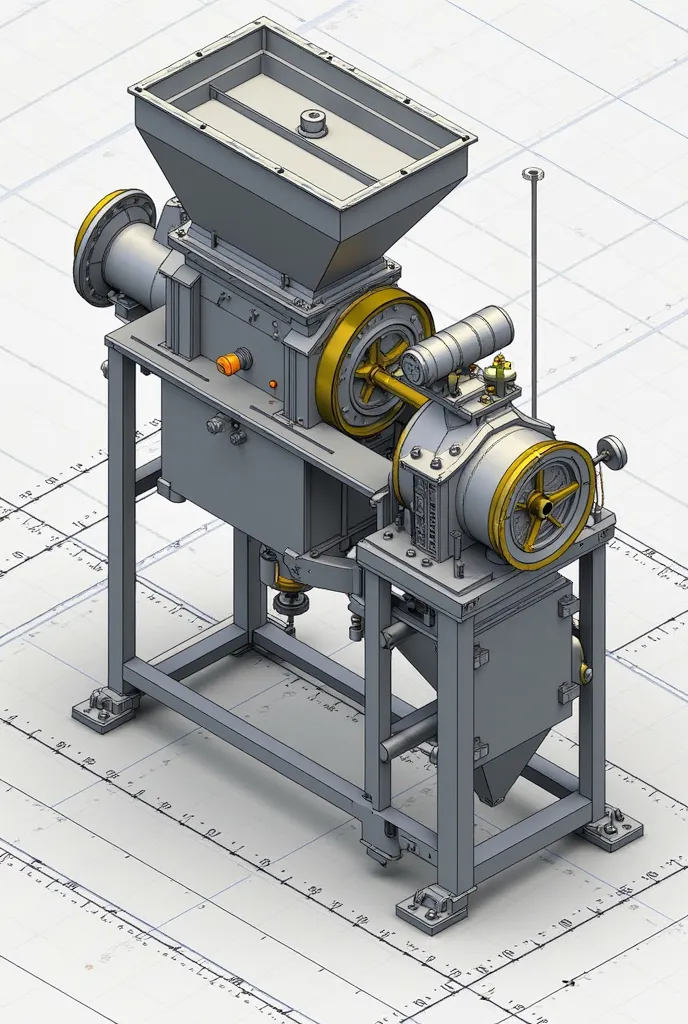

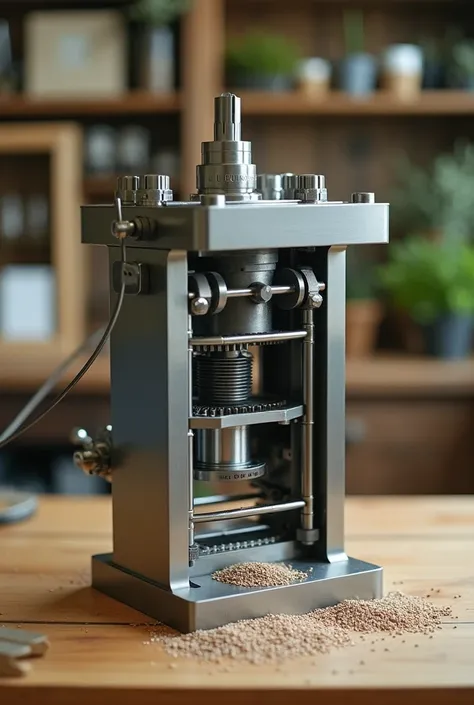

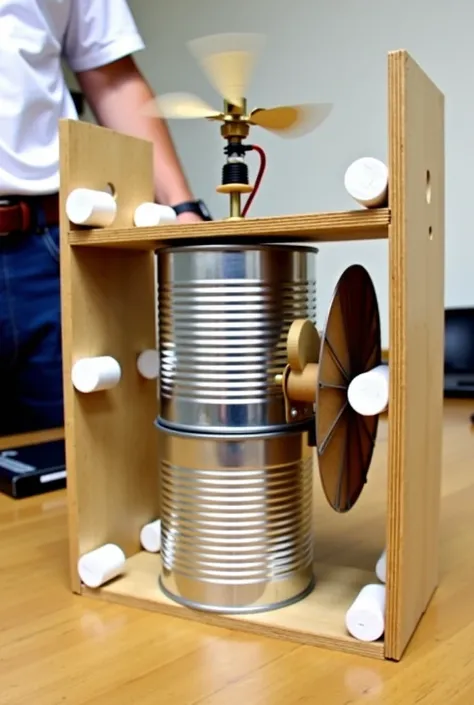

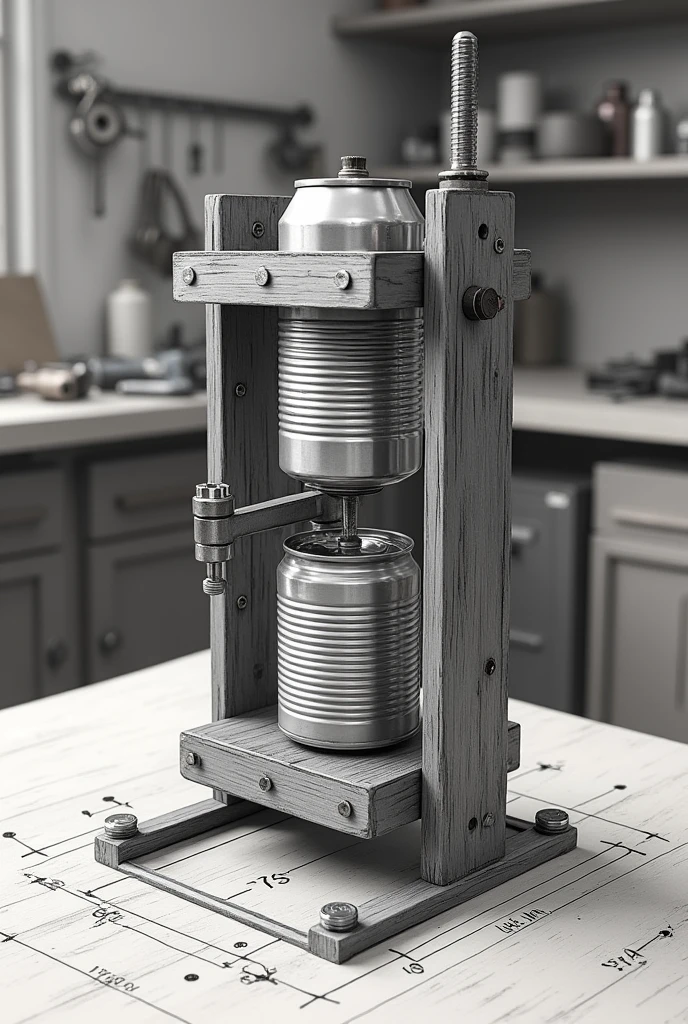

make a simple sketch of the project without people in the less robust image **Aluminum Can Press** #### **Purpose:** The aluminum can press is designed for compressing cans, reducing its volume and facilitating storage and recycling. It is ideal for homes, schools, and small businesses that want to contribute to the recycling process. #### **Materials Needed:** - Metal profiles (square tubes or angles) - Steel plates for the compression plate and base - Long metal lever (it could be an iron bar) - Return spring (optional) - High strength bolts and nuts - Electrodes and welding machine - Cutting tools (grinder, band saw) - Drill with suitable bits #### **walkthrough:** 1. **Planning and Design:** - Draw the project, defining the dimensions of the structure according to the size of the cans to be compacted. The standard height for a 350ml can is about 12cm. - Determine the height of the lever to ensure that the force applied is sufficient to compress the can. 2. **Construction of the Structure:** - Cut the metal profiles to form the base and vertical structure. The base must be robust enough to withstand the pressure applied.. - Weld the profiles forming a "L", with the horizontal base and the vertical structure. - Attach side guides to the vertical frame to keep the compression plate aligned. 3. **Compression Plate Manufacturing:** - Cut a steel plate to the appropriate size for the compression plate. It should be slightly smaller than the diameter of the can to ensure the can is compressed evenly.. - Connect the compression plate to the metal lever through a pivot point, allowing the lever to move the plate down. 4. **Lever Installation:** - Attach the lever to the top of the vertical frame. The lever must be long enough so that the operator can apply significant force.

Generation Data

Protokolle

Prompts

Prompts kopieren

make a simple sketch of the project without people in the less robust image

**Aluminum Can Press**

#### **Purpose:**

The aluminum can press is designed for compressing cans

,

reducing its volume and facilitating storage and recycling

.

It is ideal for homes

,

schools

,

and small businesses that want to contribute to the recycling process

.

#### **Materials Needed:**

- Metal profiles (square tubes or angles)

- Steel plates for the compression plate and base - Long metal lever (it could be an iron bar)

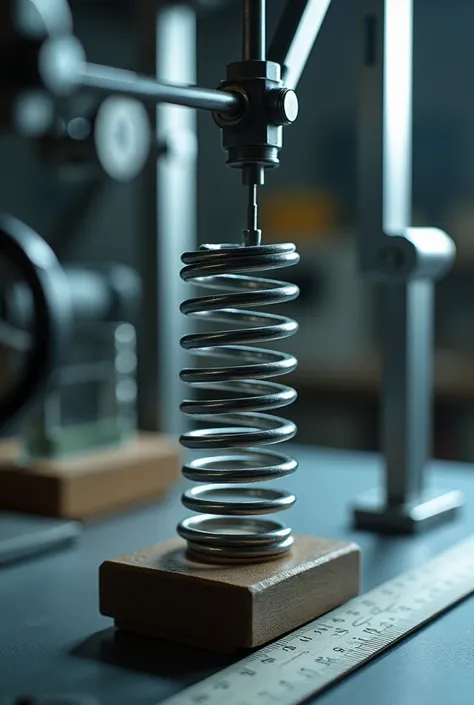

- Return spring (optional)

- High strength bolts and nuts - Electrodes and welding machine - Cutting tools (grinder

,

band saw)

- Drill with suitable bits

#### **walkthrough:**

1

.

**Planning and Design:**

- Draw the project

,

defining the dimensions of the structure according to the size of the cans to be compacted

.

The standard height for a 350ml can is about 12cm

.

- Determine the height of the lever to ensure that the force applied is sufficient to compress the can

.

2

.

**Construction of the Structure:**

- Cut the metal profiles to form the base and vertical structure

.

The base must be robust enough to withstand the pressure applied

..

- Weld the profiles forming a "L"

,

with the horizontal base and the vertical structure

.

- Attach side guides to the vertical frame to keep the compression plate aligned

.

3

.

**Compression Plate Manufacturing:**

- Cut a steel plate to the appropriate size for the compression plate

.

It should be slightly smaller than the diameter of the can to ensure the can is compressed evenly

..

- Connect the compression plate to the metal lever through a pivot point

,

allowing the lever to move the plate down

.

4

.

**Lever Installation:**

- Attach the lever to the top of the vertical frame

.

The lever must be long enough so that the operator can apply significant force

.

Info

Checkpoint & LoRA

Checkpoint

SeaArt Infinity

#Produktdesign

#SeaArt Infinity

0 Kommentar(e)

0

0

0