Make a simple sketch of the project without people in the less robust image

Generation Data

Records

Prompts

Copy

make a simple sketch of the project without people in the less robust image

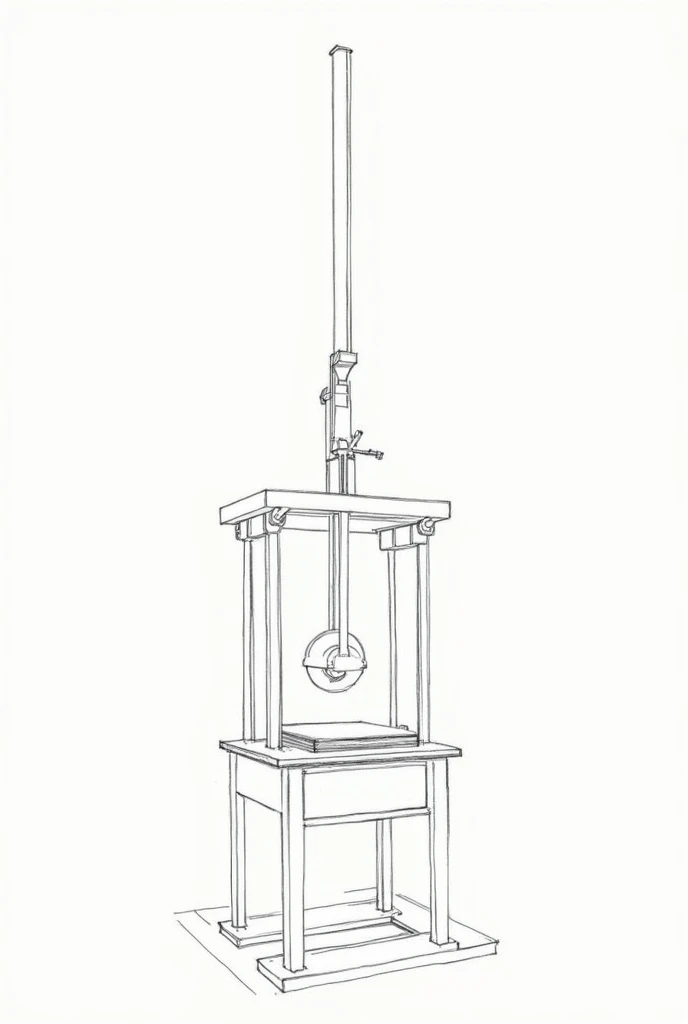

**Aluminum Can Press**

#### **Purpose:**

The aluminum can press is designed for compressing cans

,

reducing its volume and facilitating storage and recycling

.

It is ideal for homes

,

schools

,

and small businesses that want to contribute to the recycling process

.

#### **Materials Needed:**

- Metal profiles (square tubes or angles)

- Steel plates for the compression plate and base - Long metal lever (it could be an iron bar)

- Return spring (optional)

- High strength bolts and nuts - Electrodes and welding machine - Cutting tools (grinder

,

band saw)

- Drill with suitable bits

#### **walkthrough:**

1

.

**Planning and Design:**

- Draw the project

,

defining the dimensions of the structure according to the size of the cans to be compacted

.

The standard height for a 350ml can is about 12cm

.

- Determine the height of the lever to ensure that the force applied is sufficient to compress the can

.

2

.

**Construction of the Structure:**

- Cut the metal profiles to form the base and vertical structure

.

The base must be robust enough to withstand the pressure applied

..

- Weld the profiles forming a "L"

,

with the horizontal base and the vertical structure

.

- Attach side guides to the vertical frame to keep the compression plate aligned

.

3

.

**Compression Plate Manufacturing:**

- Cut a steel plate to the appropriate size for the compression plate

.

It should be slightly smaller than the diameter of the can to ensure the can is compressed evenly

..

- Connect the compression plate to the metal lever through a pivot point

,

allowing the lever to move the plate down

.

4

.

**Lever Installation:**

- Attach the lever to the top of the vertical frame

.

The lever must be long enough so that the operator can apply significant force

.

INFO

Checkpoint & LoRA

Checkpoint

SeaArt Infinity

#Item Design

#SeaArt Infinity

0 comment

0

0

0