A close up of a person holding a pair of gloves

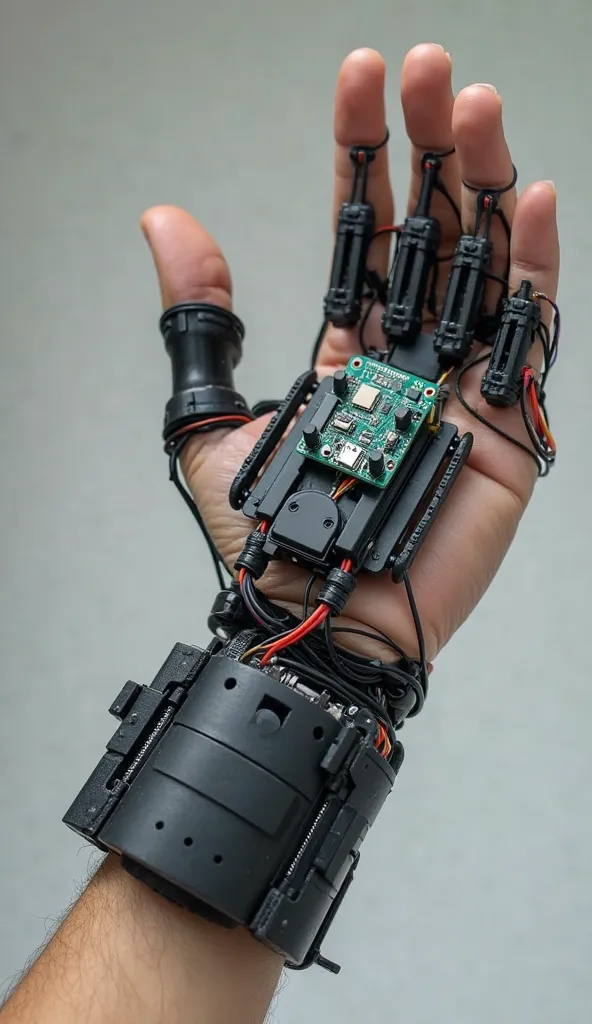

Mechanical Structure: This includes a support structure for the forearm, usually made of lightweight, sturdy materials such as aluminum alloys or carbon fiber. The structure must be designed to accommodate the electronic components, motors and sensors. Actuators: The actuators are responsible for generating the movements in the bionic forearm. They can be electric, hydraulic or pneumatic motors, depending on the specific project. Electric motors are generally preferred due to their compact size and precise control capability. Sensors: Sensors are used to capture information from the environment and provide feedback to the user. They can include pressure sensors, motion sensors, force sensors, among others. These sensors allow the user to have a sense of touch and feedback on the force exerted by the bionic forearm. User Interface: A user interface is required to allow the user to control the bionic forearm. This can be done through EMG (electromyography) sensors, which detect the user's muscle activity and translate it into commands to the bionic forearm. A control system can also be used through an app or other external device. Power Source: A bionic forearm requires a power source to power the motors, sensors, and other electronic components. This can be done through rechargeable batteries built into the forearm or through a connection to an external power source. Coating and Aesthetics: For a more realistic bionic forearm, one can add a silicone coating or other material to give it a more natural look. In addition, the overall aesthetics of the bionic forearm can be customized to suit the user's compulsive people.

Prompts

Copier les Paramètres

Mechanical Structure: This includes a support structure for the forearm

,

usually made of lightweight

,

sturdy materials such as aluminum alloys or carbon fiber

.

The structure must be designed to accommodate the electronic components

,

motors and sensors

.

Actuators: The actuators are responsible for generating the movements in the bionic forearm

.

They can be electric

,

hydraulic or pneumatic motors

,

depending on the specific project

.

Electric motors are generally preferred due to their compact size and precise control capability

.

Sensors: Sensors are used to capture information from the environment and provide feedback to the user

.

They can include pressure sensors

,

motion sensors

,

force sensors

,

among others

.

These sensors allow the user to have a sense of touch and feedback on the force exerted by the bionic forearm

.

User Interface: A user interface is required to allow the user to control the bionic forearm

.

This can be done through EMG (electromyography) sensors

,

which detect the user's muscle activity and translate it into commands to the bionic forearm

.

A control system can also be used through an app or other external device

.

Power Source: A bionic forearm requires a power source to power the motors

,

sensors

,

and other electronic components

.

This can be done through rechargeable batteries built into the forearm or through a connection to an external power source

.

Coating and Aesthetics: For a more realistic bionic forearm

,

one can add a silicone coating or other material to give it a more natural look

.

In addition

,

the overall aesthetics of the bionic forearm can be customized to suit the user's compulsive people

.

Info

Checkpoint & LoRA

Checkpoint

Deliberate

#technology

#Réalisme

#concevoir

0 commentaire(s)

0

0

0