Someone is pouring a mixture into a bowl of food on a table

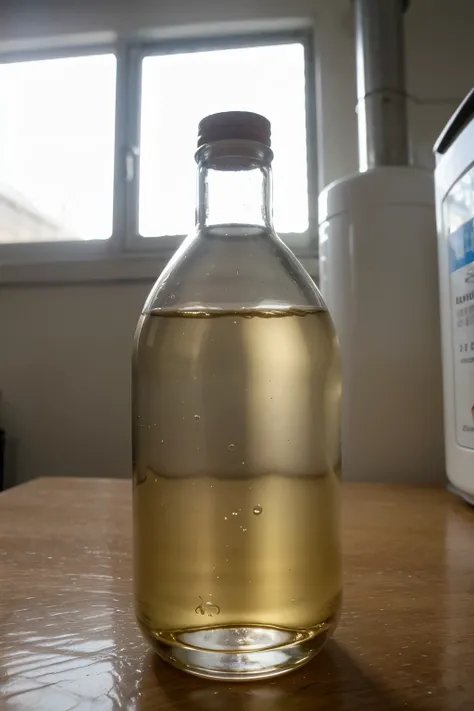

The process flow of sodium tetrachloroaluminate to prepare polyaluminum chloride is as follows: 1. Raw material preparation: prepare aluminum tetrachloride and sodium hydroxide as the main raw materials. Ensure the purity and quality of raw materials. 2. Dissolve aluminum tetrachloride: add an appropriate amount of aluminum tetrachloride to an appropriate amount of aqueous solution. Stir to dissolve aluminum tetrachloride, ensuring that it is completely dissolved. 3. Add sodium hydroxide: slowly add sodium hydroxide solution in aluminum tetrachloride solution. Stir the solution so that it mixes thoroughly. 4. Precipitate polyaluminum chloride: let the solution stand for a period of time to precipitate the formation of polyaluminum chloride. The speed and quality of precipitation can be controlled by conditions such as temperature and agitation. 5. Separate the pellet: Separate the pellet from the supernatant. The pellet can be separated by centrifugation, filtration, etc. 6. Washing: Wash the pellet with an appropriate amount of water to remove impurities and residual reactants. 7. Drying: The washed polyaluminum chloride precipitate is dried to remove residual moisture. 8. Crushing and packaging: The dried polyaluminum chloride precipitate is crushed and then packaged for storage and transportation. Draw a diagram of the device

Prompts

Copier les Paramètres

The process flow of sodium tetrachloroaluminate to prepare polyaluminum chloride is as follows:

1

.

Raw material preparation: prepare aluminum tetrachloride and sodium hydroxide as the main raw materials

.

Ensure the purity and quality of raw materials

.

2

.

Dissolve aluminum tetrachloride: add an appropriate amount of aluminum tetrachloride to an appropriate amount of aqueous solution

.

Stir to dissolve aluminum tetrachloride

,

ensuring that it is completely dissolved

.

3

.

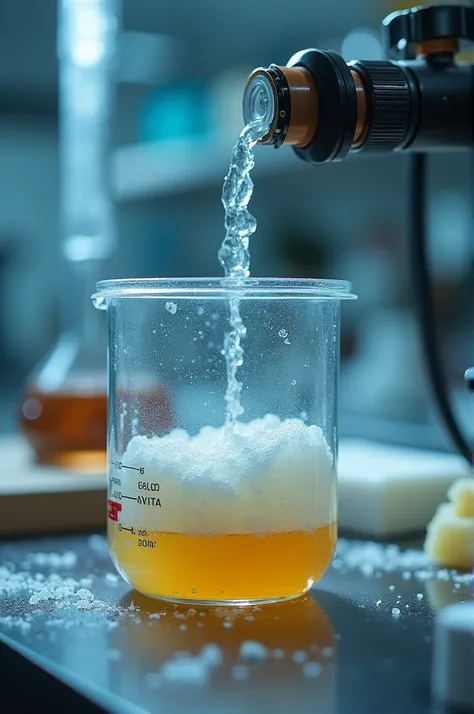

Add sodium hydroxide: slowly add sodium hydroxide solution in aluminum tetrachloride solution

.

Stir the solution so that it mixes thoroughly

.

4

.

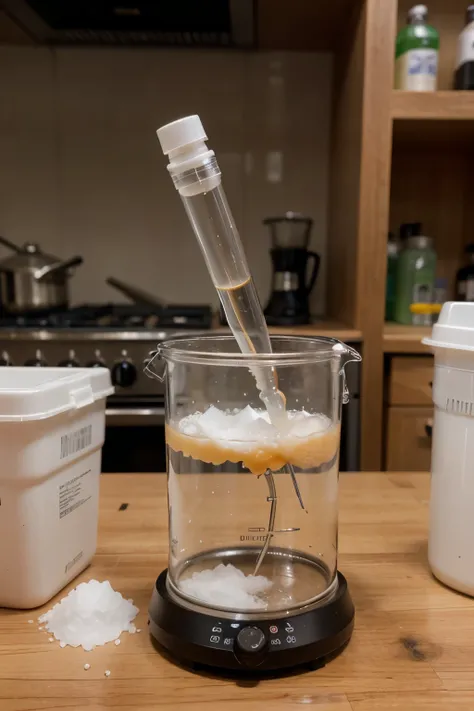

Precipitate polyaluminum chloride: let the solution stand for a period of time to precipitate the formation of polyaluminum chloride

.

The speed and quality of precipitation can be controlled by conditions such as temperature and agitation

.

5

.

Separate the pellet: Separate the pellet from the supernatant

.

The pellet can be separated by centrifugation

,

filtration

,

etc

.

6

.

Washing: Wash the pellet with an appropriate amount of water to remove impurities and residual reactants

.

7

.

Drying: The washed polyaluminum chloride precipitate is dried to remove residual moisture

.

8

.

Crushing and packaging: The dried polyaluminum chloride precipitate is crushed and then packaged for storage and transportation

.

Draw a diagram of the device

Info

Checkpoint & LoRA

Checkpoint

Colorful

0 commentaire(s)

0

0

0