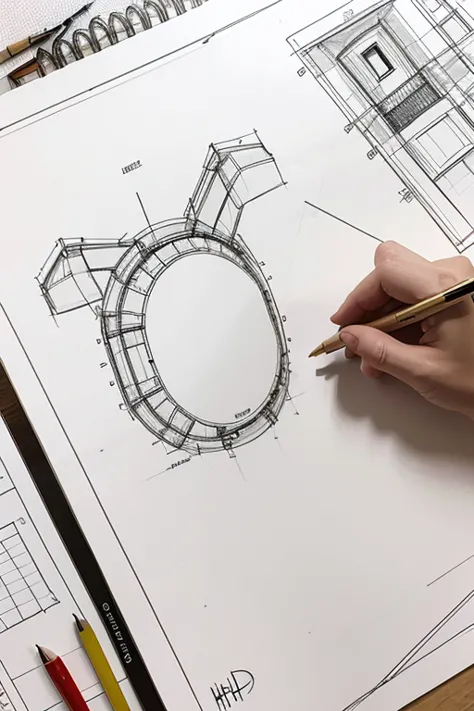

Make a sketch of this project **Manual Press** #### **Purpose

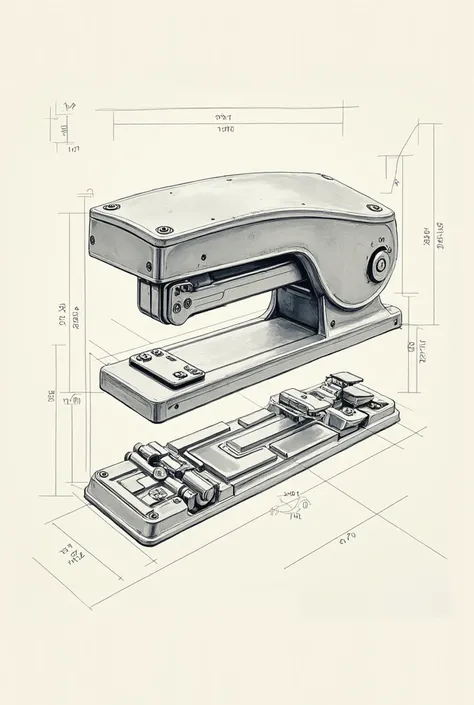

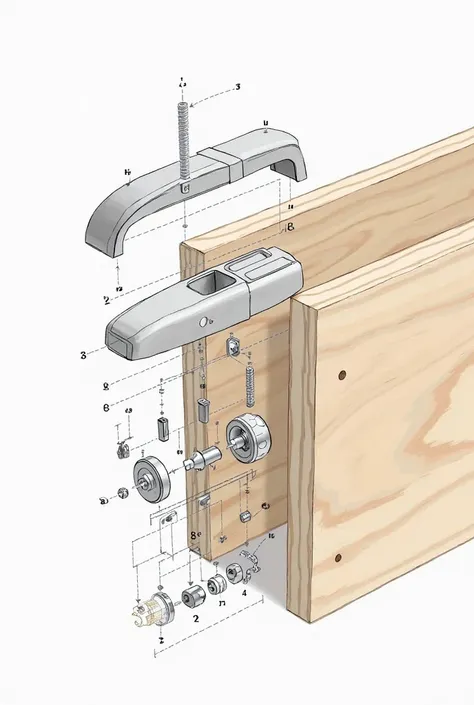

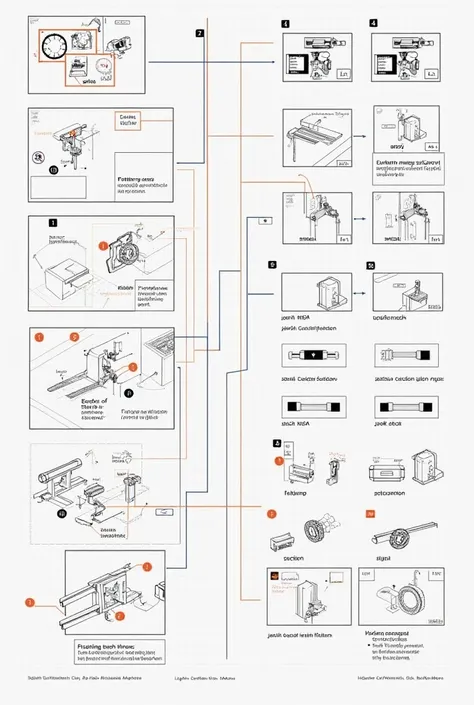

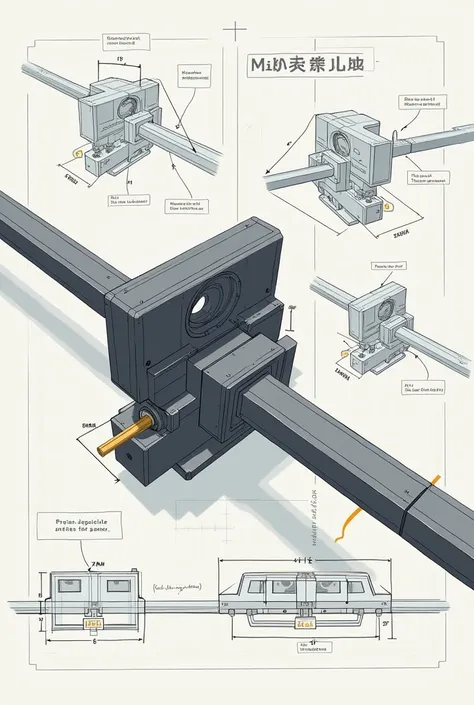

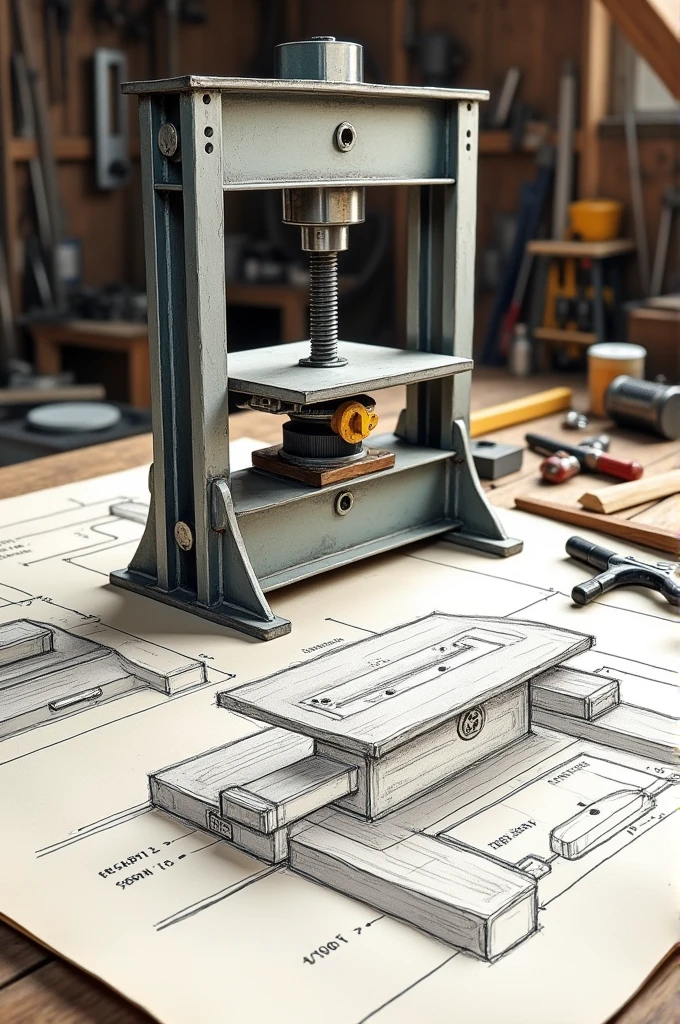

make a sketch of this project **Manual Press** #### **Purpose:** Hand press is used to apply pressure on materials for bending, press, embed bearings, cutting or other forming and assembly operations. It is ideal for small workshops, where it is necessary to perform these operations accurately and efficiently. #### **Materials Needed:** - Steel profiles (angles or U or I beams) - Steel plates (for the base and the pressing plate) - Hydraulic bottle jack (capacity from 2 to 10 tons, depending on the need) - High-strength bolts and nuts - Rails or guides (steel bars) - Electrodes and welding machine - Cutting tools (grinder, band saw) - Drill with suitable bits - Vise and other bench tools #### **walkthrough:** 1. **Planning and Design:** - Design the press on paper or CAD software, defining the dimensions based on the capacity of the hydraulic jack and the size of the parts to be worked on. - Set the size of the structure, usually a height of 1,5 meters and a width of 0,5 meters are suitable for general use. 2. **Structure Preparation:** - Cut the steel profiles to the right size to form the press frame (two side uprights and two horizontal crossbars). - Weld the horizontal crossbars to the side uprights, forming a sturdy rectangular frame. This will be the base where the jack will be mounted.. 3. **Construction of the Base and Pressing Plate:** - Cut a steel sheet for the base, where the pieces will be placed. It must be thick enough (minimum 10 mm) to withstand the pressure. - Cut another sheet for the pressing plate, which must also be thick. Weld or screw side guides to ensure the board moves vertically aligned. 4. **Hydraulic Jack Installation:** - Place the hydraulic jack on the base of the press, between the vertical uprights. - The pressing plate must be placed on top of the ca

Prompts

Copiar prompts

make a sketch of this project

**Manual Press**

#### **Purpose:**

Hand press is used to apply pressure on materials for bending

,

press

,

embed bearings

,

cutting or other forming and assembly operations

.

It is ideal for small workshops

,

where it is necessary to perform these operations accurately and efficiently

.

#### **Materials Needed:**

- Steel profiles (angles or U or I beams)

- Steel plates (for the base and the pressing plate)

- Hydraulic bottle jack (capacity from 2 to 10 tons

,

depending on the need)

- High-strength bolts and nuts - Rails or guides (steel bars)

- Electrodes and welding machine - Cutting tools (grinder

,

band saw)

- Drill with suitable bits - Vise and other bench tools

#### **walkthrough:**

1

.

**Planning and Design:**

- Design the press on paper or CAD software

,

defining the dimensions based on the capacity of the hydraulic jack and the size of the parts to be worked on

.

- Set the size of the structure

,

usually a height of 1

,

5 meters and a width of 0

,

5 meters are suitable for general use

.

2

.

**Structure Preparation:**

- Cut the steel profiles to the right size to form the press frame (two side uprights and two horizontal crossbars)

.

- Weld the horizontal crossbars to the side uprights

,

forming a sturdy rectangular frame

.

This will be the base where the jack will be mounted

..

3

.

**Construction of the Base and Pressing Plate:**

- Cut a steel sheet for the base

,

where the pieces will be placed

.

It must be thick enough (minimum 10 mm) to withstand the pressure

.

- Cut another sheet for the pressing plate

,

which must also be thick

.

Weld or screw side guides to ensure the board moves vertically aligned

.

4

.

**Hydraulic Jack Installation:**

- Place the hydraulic jack on the base of the press

,

between the vertical uprights

.

- The pressing plate must be placed on top of the ca

INFO

Checkpoint & LoRA

Checkpoint

SeaArt Infinity

#Diseño de producto

#SeaArt Infinity

0 comentario(s)

0

0

0